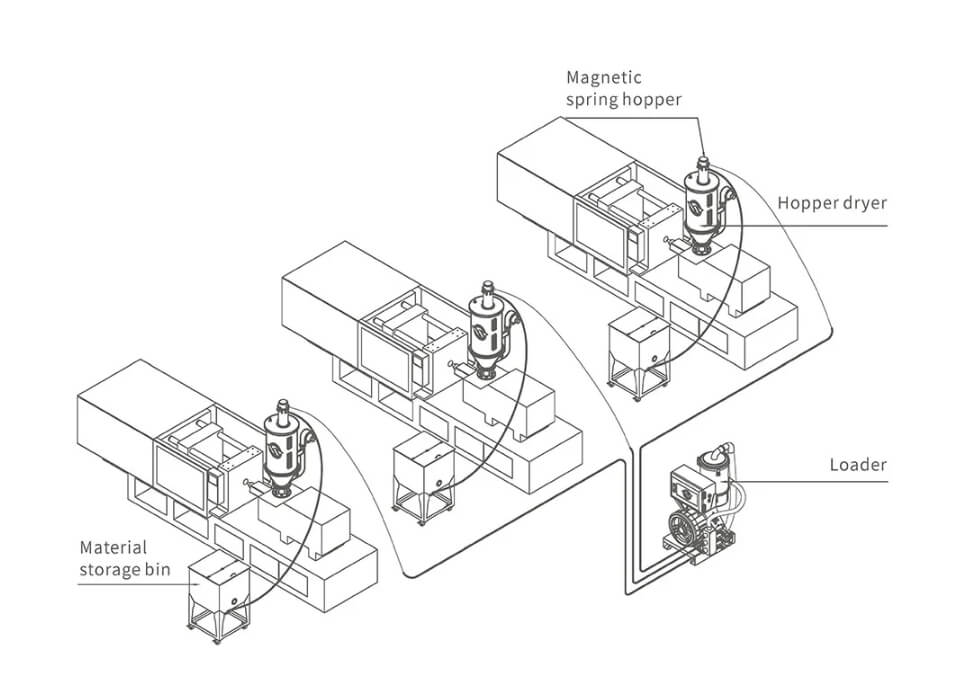

Feeding & Conveying

Central Material Handling System & Water Feeding System

Performance characteristics:Efficient pr...

1:One host loader is needed to feed to several hoppers to save cost and space.

2:Vacuum hopper and photoelectric sensor hopper are available.

3:Applicable for drying and conveying into a central feeding system.

4:Controlled by a fully automatic microcomputer.

5:Integrated control system

6:Low maintenance.

Performance characteristics

One machine pulls multiple buckets, saving equipment configuration and space. Vacuum hoppers and electric eye hoppers can be selected according to actual usage.

Especially suitable for integrated drying and feeding systems, simplifying system structure, improving usage efficiency, and facilitating operation.

Fully automatic computer operation program.

Integrated control, easy to operate, install, and debug.

Convenient and fast maintenance.

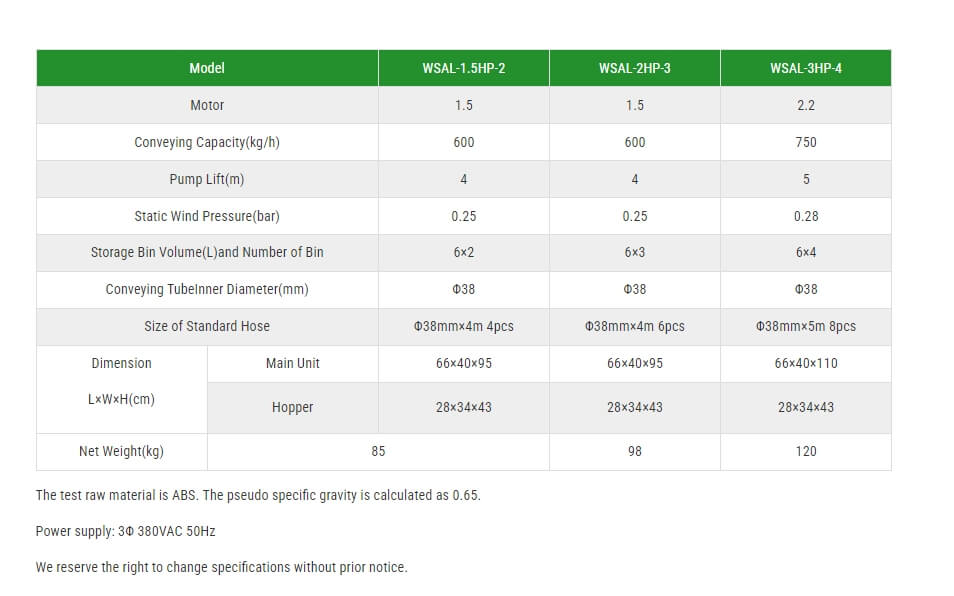

Technical Parameter

| Model | WSAL-2HP-2 | WSAL-2HP-3 | WSAL-3HP-4 | |

| Motor (kw) | 1.5 | 1.5 | 2.2 | |

| Conveying capacity (kg/h) | 600 | 600 | 750 | |

| Suction head (m) | 4 | 4 | 5 | |

| Static wind pressure (bar) | 0.25 | 0.25 | 0.28 | |

| Storage bucket capacity (L) | 6×2 | 6×3 | 6×4 | |

| Inner diameter of feeding pipe (mm) | Φ 38 | Φ 38 | Φ 38 | |

| Delivery pipe | Φ 38mm×4m 4pcs | Φ 38mm×4m 6pcs | Φ 38mm×5m 8pcs | |

| Overall dimensions L×W×H (cm) | host | 66×40×95 | 66×40×95 | 66×40×110 |

| hopper | 28×34×43 | 28×34×43 | 28×34×43 | |

| Net weight (kg) | 85 | 98 | 120 | |

The testing material is ABS; False specific gravity: 0.65 calculation; Power supply: 3 Φ 380VAC, 50Hz;

The product specifications are subject to change without prior notice.