Analysis of Blade Gap in Plastic Crushers

2025-07-02 Page view:

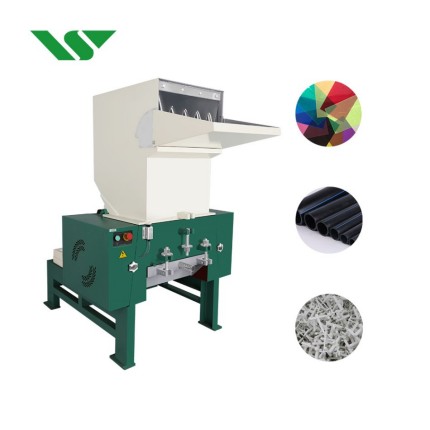

Plastic crushers are widely used in plastic recycling and waste processing. The blade gap setting plays a critical role in crushing efficiency, equipment performance, and maintenance costs. This article examines the function of the crusher blade gap, methods for adjusting it, and its impact on the overall performance of the equipment.

1. The Function and Importance of the Blade Gap

A plastic crusher works by breaking down plastic waste into smaller particles, making them easier to recycle. The blade gap refers to the space between the fixed and rotating blades, directly influencing the crushing quality and machine efficiency.

Crushing Effectiveness:

If the blade gap is too large, the cutting process becomes incomplete, resulting in poor crushing quality and potential material blockages. Conversely, a blade gap that is too small leads to increased friction, accelerating blade wear and raising energy consumption.

Equipment Longevity:

An optimized blade gap reduces wear on key components, extending the lifespan of the blades and other parts. A proper gap prevents excessive blade wear, thus reducing the need for frequent maintenance or replacements.

Energy Efficiency:

The size of the blade gap also affects motor load. When the gap is too small, the motor has to overcome higher resistance, leading to increased energy consumption. A well-adjusted gap lightens the motor's load, improving energy efficiency.

2. How to Adjust the Blade Gap

Adjusting the blade gap should be based on the type of plastic material, its thickness, and the crusher model. The following factors are crucial for proper adjustment:

Material Hardness and Thickness:

Harder plastics may require a larger blade gap to facilitate easier cutting, while softer plastics benefit from a smaller gap to ensure precision in the cut.

Equipment Specifications and Blade Design:

Different crusher models have various blade designs. Adjustments should follow the manufacturer's recommended gap range to ensure optimal performance.

Operator Experience and Maintenance:

Experienced operators can monitor blade wear over time and make periodic adjustments to the gap to maintain stable performance.

3. Common Issues and Solutions

During use, improper blade gaps can affect equipment performance. Here are some common issues and how to address them:

Poor Crushing Performance:

If the crushing performance is subpar, the blade gap may be too large. Reducing the gap can enhance blade contact and improve crushing efficiency.

Accelerated Blade Wear:

Excessive blade wear could be a sign that the blade gap is too small. Increasing the gap will reduce friction, extending blade life.

Increased Energy Consumption:

If there is a noticeable increase in energy usage, the gap may be too small, causing the motor to work harder. Adjusting the gap can help reduce energy consumption.

The crusher blade gap is a crucial factor in the performance of plastic crushers. Proper adjustment improves crushing efficiency, extends the life of the equipment, and reduces energy consumption. Operators should regularly check and adjust the blade gap based on material characteristics and equipment requirements to ensure optimal operation of the machine.