Drying & Dehumidifying

WSDA Cabinet Dryer For Injection Molding Machine

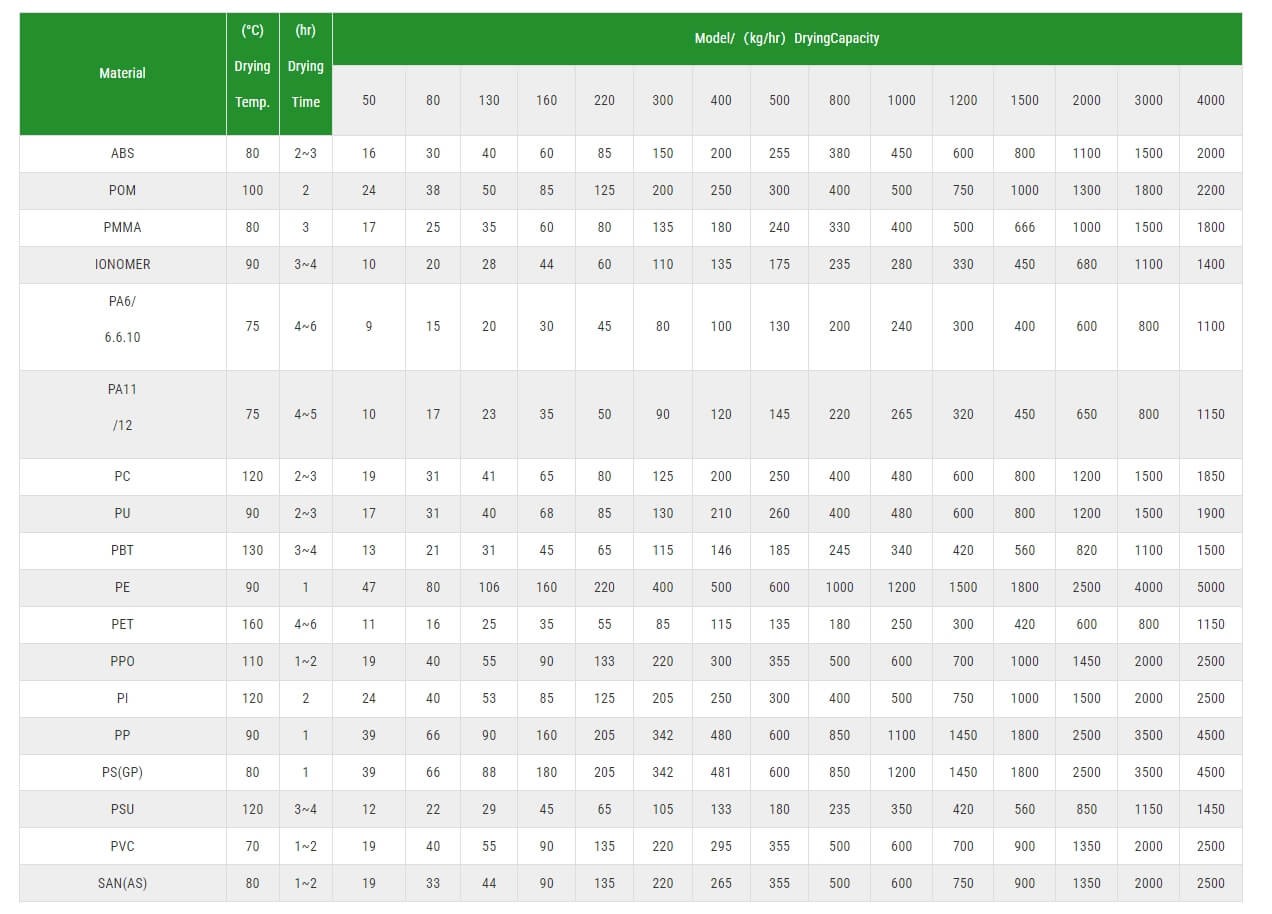

Widely suitable for drying any plastic r...

1.Air bubbles, shrinkages, cracks, sink marks and poor transparency occur when hygroscopic plastic material do not dry completely before molding. Hygroscopic materials such as PA, PC, PBT, PET,

and nylon, contain humidity and cannot be dried completely by hopper dryers.

2.With a dehumidifier, its honeycomb rotor provides drying air with dew point under -40°C to remove the humidity within the materials and reduce it to 0.02% before molding.

Working Principle

The main reason for poor quality such as bubbles, silver lines, cracks, flow marks, and poor transparency is that the plastic is not fully dried before forming. Engineering plastics such as PA, PCPBTPETNYLON, and other materials with strong moisture absorption, cannot be completely dried by traditional dryers due to water infiltration into the plastic particles.

It has been proven through practice that reducing the dew point of the drying air to below -40 ℃ while controlling the heat to blow it over the surface of wet plastic particles can reduce its moisture content to below 0.02% before molding. The honeycomb dehumidifier, on the other hand, utilizes a honeycomb wheel in a closed circulation system to fully dehumidify the air and quickly release moisture from the plastic particles to achieve dehumidification and drying effects.