What are the advantages of plastic materials in new energy vehicle components?

2023-09-22 Page view:

At present, with the continuous rise of Chinese automobile brands, automotive components, from interior parts to engine casings, have entered a trend of lightweight; Therefore, plastic processing technology is becoming increasingly mature and the industry attaches great importance to it. It also encourages more manufacturers to choose to use plastic processes for the production of automotive parts. So what are the specific advantages of automotive plastic parts reflected in, and how do they affect car performance, design, and sustainability? Let's take a look together.

Let me first tell you about the current recycling rate of new energy vehicles:

Volvo Cars has released a brand new small pure electric luxury SUV. In terms of materials, recycled plastic accounts for 17%, including interior components, exterior bumpers, etc. The recycling rate of the scrapped vehicle can reach 95%.

A certain number of cars use a large amount of recycled materials in their ID. models and plan to promote them to the entire ID series. The interior components are made of marine recycled plastic and produced using 64 500ml PET bottles. The seat surface is made of Seaqual yarn, which contains 10% marine ingredients and 90% recycled PES yarn, while the seat cover also contains 71% recycled material. The roof and floor surfaces are both made of 100% recycled polyester, and the insulation layer of the carpet is also made of recycled plastic. Other components, including the underbody cover and the inner surface of the wheelhouse, all contain recycled plastic.

Plastic components in the production of new energy vehicles have the characteristics of lightweight, environmental protection, high durability, high completion rate of complex geometric structures, energy conservation, environmental protection, and cost reduction. Being able to meet the requirements of lightweight and green environmental protection for new energy vehicles is the main material for interior preparation of new energy vehicles at present and for a long time in the future.

The main roles of plastic technology in the automotive industry are as follows:

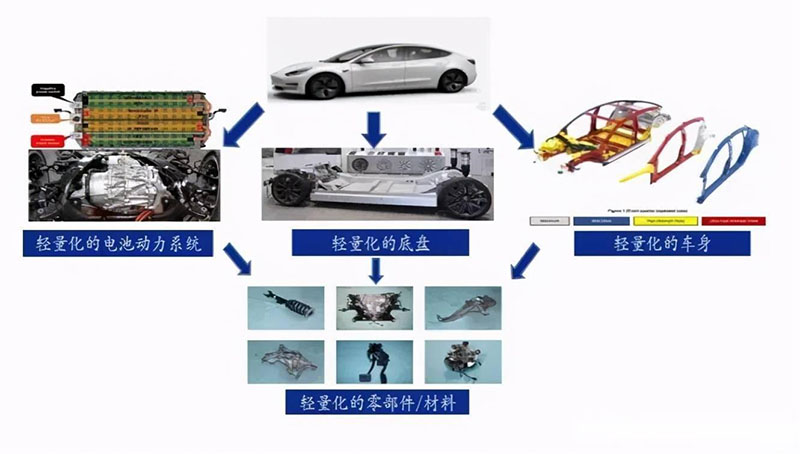

Lightweight design; Injection molding can use lightweight plastic materials to replace traditional metal components. This reduces the total weight of the car, improves fuel and electricity efficiency, and improves environmental performance.

Complex geometric structure: Plastic technology can manufacture complex components such as instrument panels, door panels, seat components, etc. These components can have complex curves and geometric shapes, making them difficult to produce using traditional manufacturing methods

Durability and performance: Automotive components must operate under extreme conditions, and manufacturing materials can be adjusted according to production needs to meet requirements such as high temperature, high pressure, and wear resistance. At the same time, it has excellent impact resistance, ensuring that the car provides protection during collisions.

Energy conservation and environmental protection: During the processing process, there is less waste plastic generated. In addition, using recyclable plastic materials can reduce waste and environmental burden.

Cost effectiveness: Injection molding is a relatively cost-effective manufacturing method, particularly suitable for large-scale production as it can quickly manufacture a large number of identical or similar components.

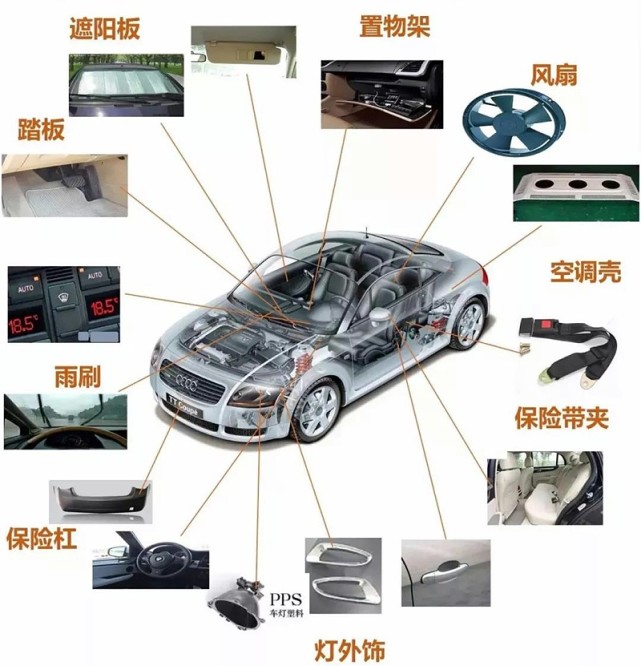

What are the components of a car that use plastic parts?

Interior parts: can be used to manufacture dashboard, door panels, seat components, center console, and interior details, providing comfort, aesthetics, and functionality.

Engine components: Many engine components, such as fan blades, fuel tank, air filter housing, etc., require high temperature and corrosion resistance to protect the normal operation of the engine.

Luminaires and lenses: The lenses for automotive headlights, taillights, and indicator lights are usually made of optical grade plastic injection molding to ensure good optical performance.

Electronic components: Many electronic component casings and brackets are also made by injection molding, and these components are used in automotive electrical systems and electronic control units.

Suspension components: Some suspension components are manufactured using high-strength plastic to provide lightweight and corrosion resistance performance

Sustainability and Future Prospects

With increasing attention to environmental protection and sustainability, car manufacturers are actively seeking sustainable materials and manufacturing methods. In the production process, by crushing and recycling defective products and reusing raw materials, effectively reducing environmental pollution and material waste; Not only does it avoid waste of raw materials, but it is also an important choice for future sustainable development. This will help reduce the environmental impact of automotive manufacturing and make the entire industry more sustainable. With the continuous progress of technology, Wensui plastic auxiliary machinery will continue to play a crucial role in the automotive industry, driving the industry towards a more sustainable future.